| Home | Email:info@engineeringplastic.cn

Contact Us

Add: No.99, Hengshan Road, Jianxi District, Luoyang, China

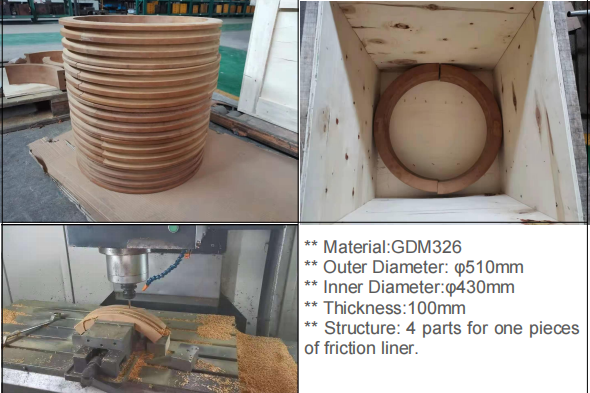

Friction liner for Full Scale Crash Test Facility

All over the world, our materials guarantee an optimal coefficient of friction between the wire rope and the sheave. Alongside the classical areas of application such as mining and funicular railways, you will find our products in cable winches, fairground rides, steel rolling mills, crash test facilities and many other applications where traction and safety matter.

friction liner’s feature:

1. Under various working conditions, the friction coefficient of GDM326 friction liner is greater than 0.28.

2. It has high mechanical properties, no harmful material to damage the wire rope, and it is easy to process the rope groove onsite.

The friction coefficient in different stiuation:

| Surface pressure Situation | 8 KJ/cm2 | 12 KJ/cm2 | 16 KJ/cm2 | 20 KJ/cm2 | 25 KJ/cm2 | 30 KJ/cm2 |

| Dry | 0.55 | 0.55 | 0.51 | 0.51 | 0.49 | 0.49 |

| Wet | 0.60 | 0.60 | 0.60 | 0.61 | 0.62 | 0.62 |

| Lubricated with turex604 | 0.36 | 0.34 | 0.34 | 0.33 | 0.30 | 0.30 |

Related products

MESSAGE

Copyright © 2017 All rights reserved CIC Luoyang Mechanical Engineering Technology Co,.LTD