| Home | Email:info@engineeringplastic.cn

Contact Us

Add: No.99, Hengshan Road, Jianxi District, Luoyang, China

Hot Sale Ball Mill Hollow Shaft

Product Description

ball mill cover parts, mill end cover, casting steel end cover

Ball mill end cover:

1. Material: ASTMA-27 grade 70-40 Class 1

2. Heat treatment:Q.T.

3. NDT: ASTM E-709 and ASTM E-125

Ball mill end cover:

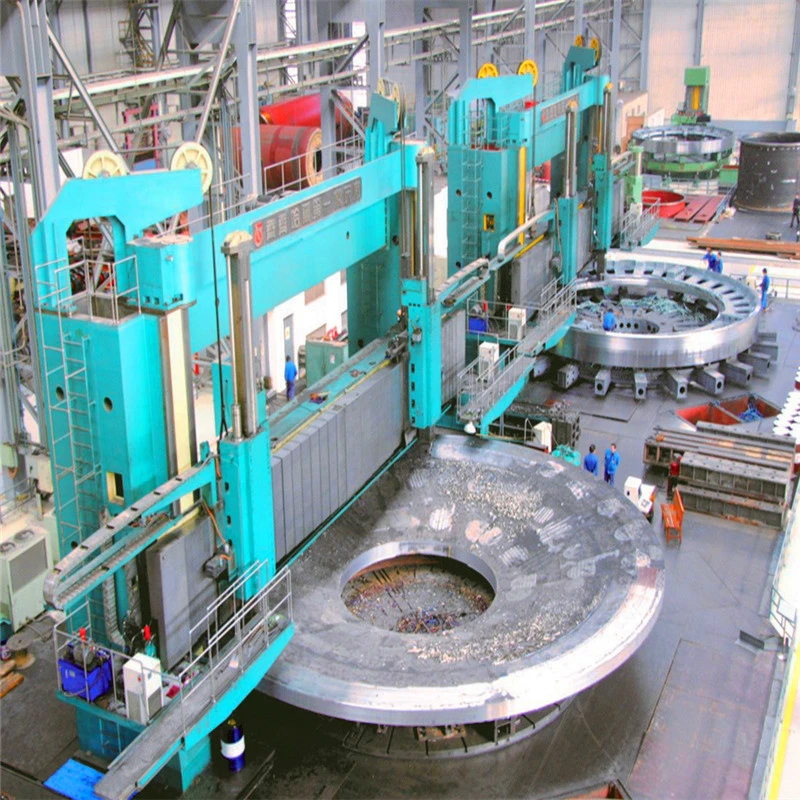

We are professional supplier in producing mill components and cement kiln components. Our components can meet the requirement of most kinds of mills. We supply components service not only for mill manufacturer but also for whom in maintaining.

1. Material: ASTMA-27 grade 70-40 Class 1

2. Mechanical Property

|

Yield Strength |

≥275 MPA |

|

Tensile Strength |

≥485MPA |

|

Elongation |

≥22MPA |

We have experienced QCP successfully executed for quality controlling for many years. We have the honor that we are ability to guarantee the foundry quality against so large steel casting. It's very important for us to decrease the cost and short the delivery in subsequent processing. The material of mill head is normally selected low carbon steel and low alloy steel. Distinctively we're good at refining on all key knots, including chemical elements controlling in foundry and subsequent heat treated. Thus we have the ability to keep the material grasping the maximum potential perfermance.The products even if in frequently working condition or very cold circumstance can possess prolong service life

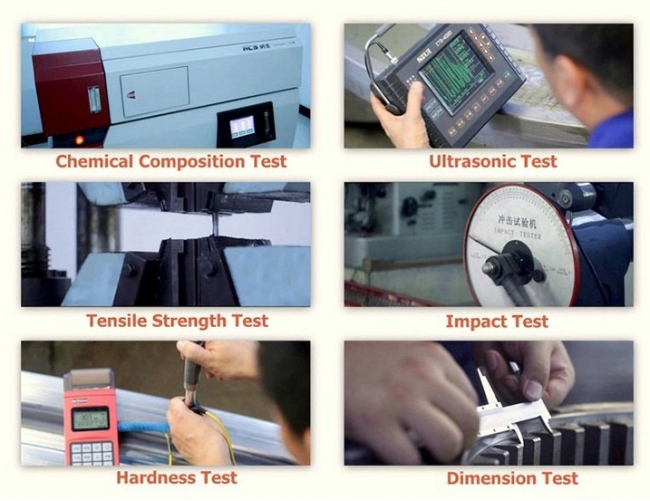

Processing and final Inspection to be taken by NDE according with ASTM and ISO standard, including UT and MPI .TPI to be acceptable yet.

|

|

Item |

structural features |

processing measure |

Test content |

|

1 |

cylinder |

|

|

|

|

|

End cap and Hollow shaft |

|

|

|

Related products

MESSAGE

Copyright © 2017 All rights reserved CIC Luoyang Mechanical Engineering Technology Co,.LTD