08

2025

-

05

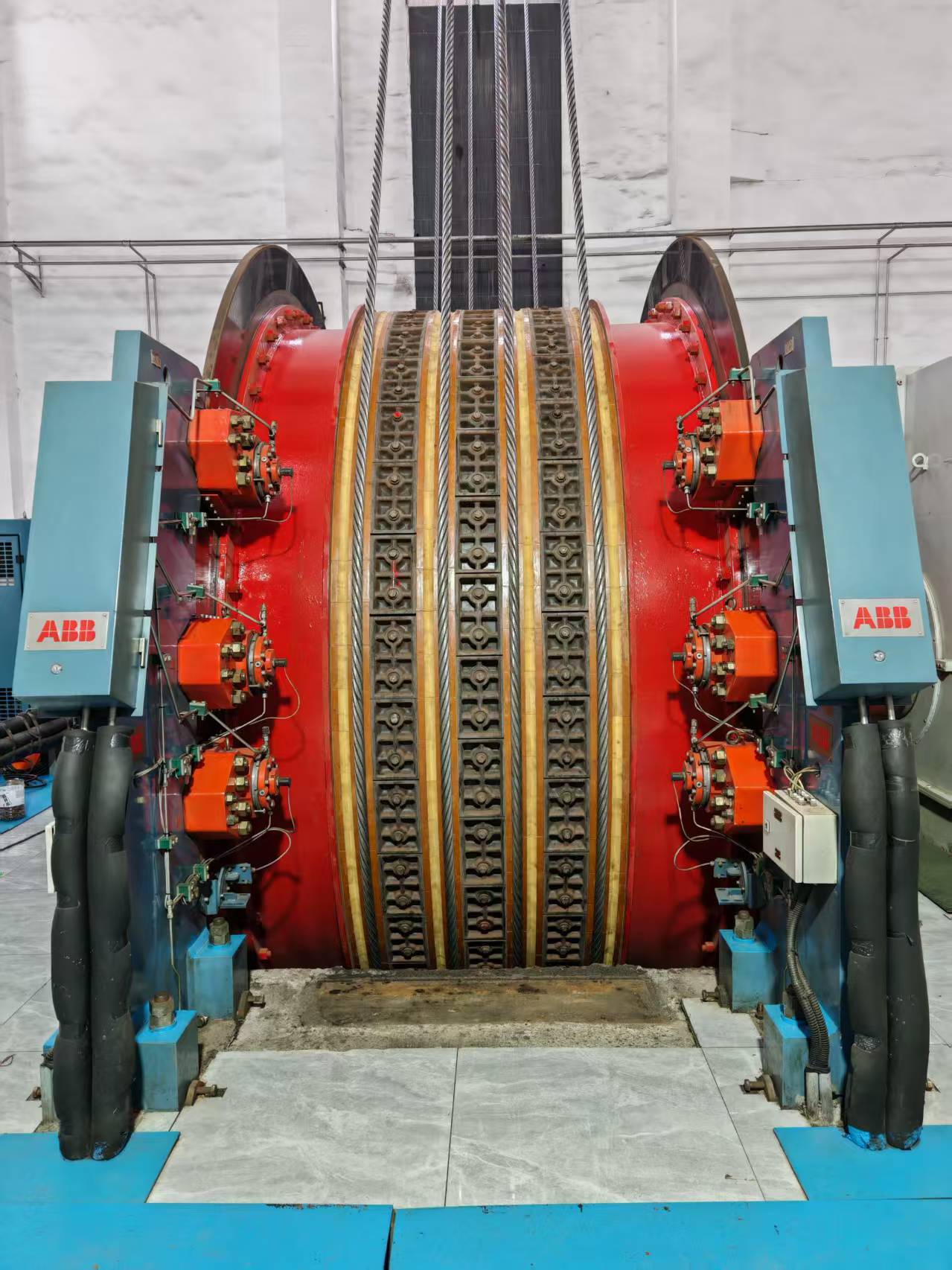

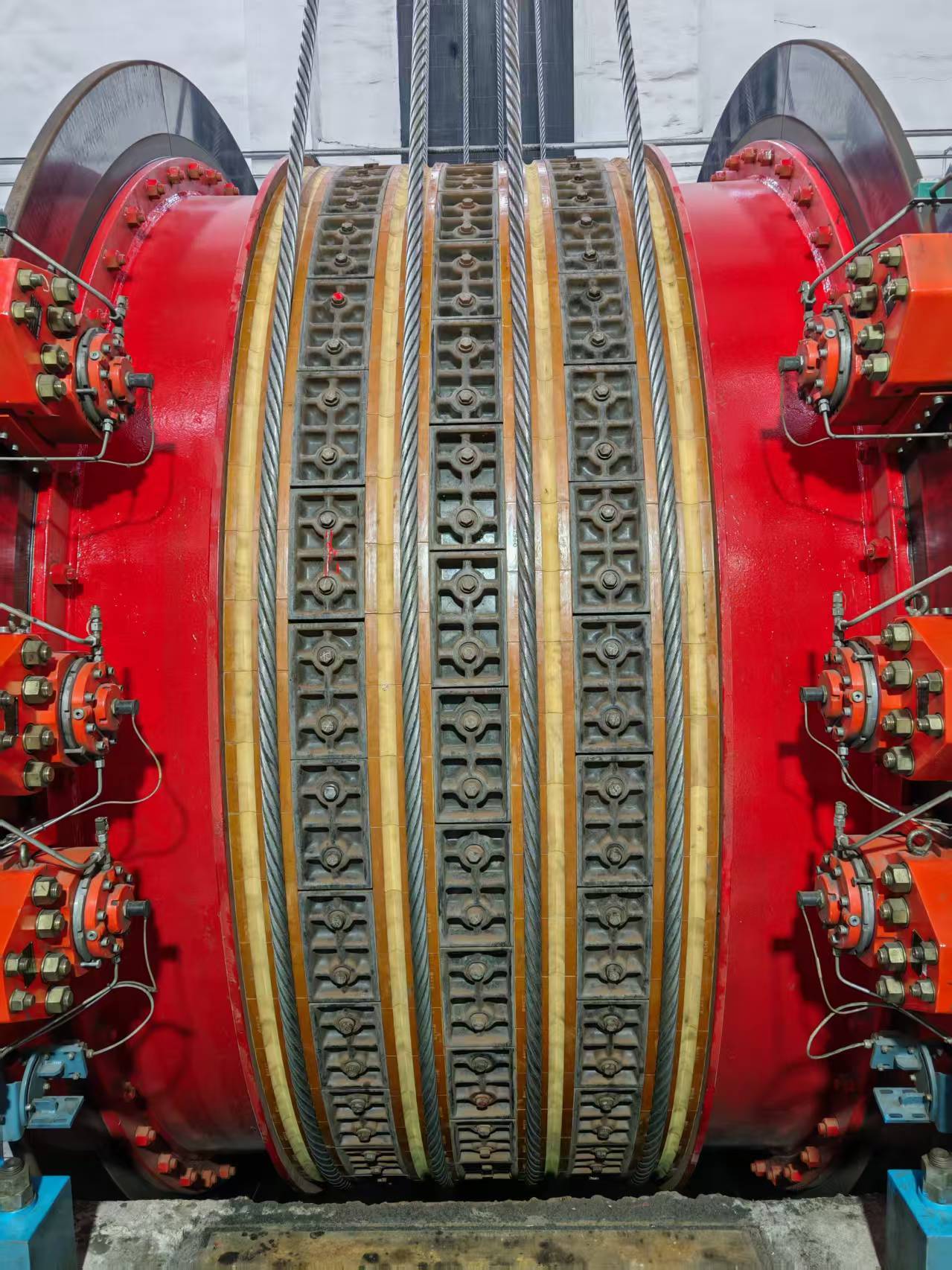

After sales personnel replaced GDM326 friction linings for the coal mine

Author:

In the coal mining industry, the efficiency and safety of machinery play a crucial role in ensuring smooth operation. One of the key components in mining equipment is the friction lining, which is crucial for the effective operation of mine hoists. Recently, after-sales personnel have been responsible for replacing the GDM326 friction lining in coal mines.

After a routine inspection revealed severe wear, it was decided to replace the GDM326 friction lining. After training to evaluate the condition of components and machinery, after-sales personnel found that the existing lining has reached its service life.

On the day of replacement, the after-sales personnel arrived at the site with new friction lining and the necessary tools for work. They conducted a thorough evaluation of the machine to ensure that all components were in good condition and prepared for the new lining. This attention to detail sets the experienced service team apart; They can not only replace parts, but also evaluate the overall health of the equipment.

After ensuring that the components are in optimal condition, a new GDM326 friction lining was installed. The team strictly follows the manufacturer's guidelines to ensure that the lining is installed correctly and securely. After installation, the machine underwent a series of tests to confirm whether the new lining was operating as expected. This includes checking for correct engagement, smooth operation, and effective braking performance. The successful replacement of GDM326 friction lining allows the equipment to operate more efficiently, reduce the risk of accidents, and improve overall productivity.

In summary, the replacement of GDM326 friction lining by coal mine after-sales personnel demonstrates the importance of proactive maintenance and service team expertise. By identifying signs of wear and taking immediate action, the staff ensured the safety and efficiency of mining operations. The joint efforts of the service team, mine management, and GDM326 friction lining quality have led to successful results, strengthening the concept of regular maintenance and quality components being crucial in the harsh environment of coal mining.

friction linings,GDM326,Koepe winder ,ABB winder