04

2025

-

09

Rope-regrooveing service for tower mounted friction winder from CIC LUOYANG compangy

Author:

Amanda

Technical training+rope regrooving services

Recently, CIC LUOYANG received an urgent request from a certain iron mine in Handan: on the one hand, it needs to provide special training for the technical personnel of the mine to maintain the rope groove of the hoist, and on the other hand, it needs to complete the rope groove turning services for two set of tower mounted friction hoists, JKM-4×4 and JKM-2.8 ×4. As the "vertical transportation lifeline" of the mine, the safe and stable operation of the hoist is directly related to production efficiency. The company's after-sales team quickly formed a special team for "technical training+on-site operation" and rushed to the site to start the "double line task" several hundred meters underground.

After arriving at the iron mine, the team did not rush to go down the mine shaft, but immediately engaged in in-depth communication with the mining personnel. The JKM-4×4 and JKM-2.8×4 friction winder have different levels of rope groove wear and maintenance requirements. ”The person in charge of mining equipment introduced. Based on this situation, the team quickly adjusted the plan: the training session will provide specialized explanations on the structural differences, rope groove wear patterns, and maintenance parameter standards between the two models; In the homework process, differentiated turning plans are developed based on the equipment's operating years and wear data, ensuring a close integration of training and practical experience.

At the same time, the team also collaborated with the mining company to verify the safety regulations for underground operations, confirm the load limits of the cage, the passage routes of the tunnel, and emergency contact information, and make sufficient preparations for subsequent underground tasks. To teach the mining masters maintenance skills and efficiently complete the rope regroove , every detail must be considered, "said the team's technical leader, Mr. Si.

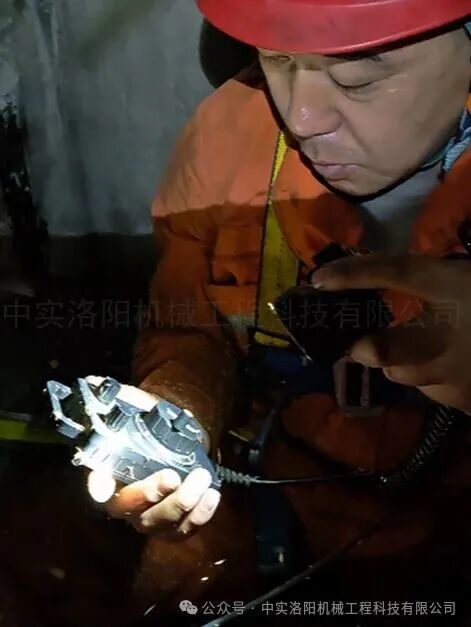

The underground work site is located several hundred meters underground, and the first step is to take a mining cage. As the steel cable slowly descends, the lights on the wellbore gradually blur, and the cage arrives at the underground transfer station, which is still 2 kilometers away from the work site. At this moment, the "test" of the underground environment officially begins: the underground space is narrow, the lighting is insufficient, the temperature is high and relatively hot, and the ventilation is poor. Team members need to carry handheld equipment on their shoulders, sometimes bend down to avoid the pipelines at the top of the tunnel, and sometimes flank around the accumulated materials. Hang in there, the homework point is ahead! "Mr. Si walked in front of the team, occasionally turning back to count personnel and equipment to ensure that no one was left behind. After a difficult journey, the team finally arrived at the hoist operation site.

After arriving at the operation site, Mr. Si conducted an "immersive training" for the technical personnel of the mining party by combining the physical lifting machine.

In the theoretical explanation section, Mr. Si transformed the complex mechanical principles into the language of "grounding": "The rope groove is like the 'shoes' of the hoist, uneven wear and tear will cause' walking and twisting feet '. The purpose of our training is to teach everyone how to' repair shoes' and how to 'protect shoes'." At the same time, we also provided detailed explanations of common faults, daily inspection points, and emergency response methods for two types of hoists, and displayed past maintenance cases on mobile phones, making abstract technical knowledge intuitive and easy to understand.

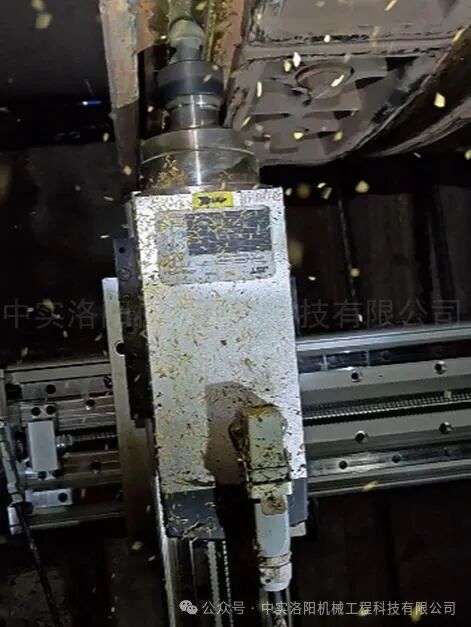

Practical training will be promoted synchronously with turning operations. Next to the JKM-4 × 4 hoist, the company manager first demonstrated the installation of the equipment, while the mining technical personnel carefully recorded and attempted to adjust the equipment parameters under guidance. The engineer company manager taught the mining personnel the operation hand in hand, and deliberately slowed down the speed when encountering key steps to ensure that the other party fully grasped them

After continuous efforts, the team successfully completed two tasks: the rope groove turning accuracy of JKM-4 × 4 and JKM-2.8 × 4 friction winder also reached the industry standard, and after testing by the mining party, fully met the requirements for safe operation; The technical personnel of the mining party have also mastered the skills of rope groove detection, daily maintenance, and simple fault handling for two types of elevators, and can independently complete basic rope groove grinding operations.

During the trip to Handan Iron Mine, the after-sales team of CIC LUOYANG not only ensured the safe operation of the "lifeline" of the mine with professional technology, but also left an "unbreakable technical team" for the mining party through the training mode of "teaching people how to fish". In the future, the company will continue to uphold the concept of "technology empowering customers, service creating value", providing more enterprises with the dual guarantee of "customized training+high-quality service", and writing more chapters of responsibility and accountability in the field of mining friction improvement.

Friction linings ,rope regroove serive ,CICLUOYANG ,Friction hoist ,friction winder

Previous page